Project QE Services

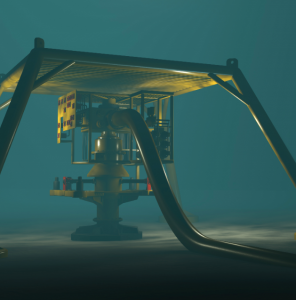

Eacon AS has Quality Engineers with experience from the subsea industry. All resources are familiar with relevant standards for the maintenance and recertification of subsea equipment.

All Eacon’s QC resources has access to the EQT tool on project assignments. The use of EQT ensures efficient generation of SDRLs, thus giving our clients a potential for increased efficiency in both the start-up and execution of a project.